Hemos discutido algo sobre estos sistemas en el foro. Les dejo un articulo que ayuda a portar un poco sobre estos sistemas. Cabe destacar que el Cuerpo de Bomberos de Calama adquirió varias unidades (4 si no me equivoco) con estos sistemas por lo cual serían los primeros carros en Chile que cuentan con estos sistemas incorporados a las bombas (no portátiles).

Link del articulo original: http://www.fireapparatusmagazine.co...nt-of-contents-fires-using-water-vs-cafs.html

To CAFS or Not: A Comparative Study on Extinguishment of Contents Fires Using Water vs. CAFS

07/09/2015

BY STEVE GREEN

On December 12, 2014, the Southlake (TX) Fire Department, in cooperation with the Johnson County (TX) ESD1 Training Center, conducted a series of live fire experiments.

The following is a synopsis of what transpired during those live burns. This article is not meant to be a position paper on the use of compressed air foam systems (CAFS), nor does it prescribe one method of extinguishment over another. As always, follow your departmental guidelines regarding suppression techniques.

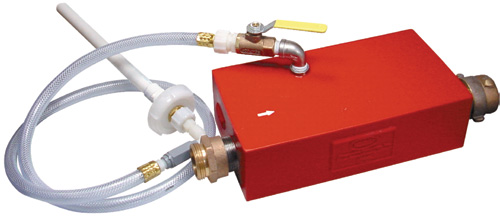

The What

CAFS is not a new piece of technology that just appeared on the fireground. In our area, we have had some departments actively deploying CAFS on the fireground for more than nine years. What is very much "up in the air" is its effective usage in urban environments here in the Metroplex area. The area known as the Metroplex encompasses Dallas/Fort Worth, Texas. Many departments have purchased these rigs and deployed them throughout their fleets. The manufacturers have been very good with initial training on operating the actual systems. There are also plenty of "experts" in the field of CAFS who are willing to come train your department. What is not standard nationwide is the acceptance of CAFS as an initial attack method. It is misunderstood and often not set up correctly-many apparatus operators are not familiar with the maintenance and upkeep of their systems. This altogether represents the higher costs often associated with the actual system. I have heard too many individuals comment that these systems are "a waste of money," that they are "glad it's out of service today," or comment that "we just need to stick with water." As with many "new" pieces of technology, training and experimentation are ways to overcome many of these misconceptions.

We could not acquire enough structures representative of construction found in the Metroplex. To be as realistic as possible, we acquired contemporary furnishings common to all jurisdictions. Mattresses, chairs, couches, and wood-component nightstands and dressers are very common products found in all bedrooms throughout the country. (Photos by author.)

The Idea

After the Southlake Fire Department acquired its newest engine, some members and I were flowing this apparatus in a parking lot during the spring of 2014. Not having used CAFS that much before, we found the results rather interesting. We had also borrowed a nozzle from another department to do some minimal testing. Afterward, we actually had more questions than answers. Basic operation of the system is easy, but the application results were different than when we used water. As a member of the Fire Instructors Association of North Texas (FIANT), I started contacting some of my other instructors about information, tactics, and so on as they related to CAFS. Now fast forward about three months to the summer of 2014. I put a study group together to evaluate the differences between CAFS and water. After about five to six months of planning, scheduling, and rescheduling, we managed, as a group, to get this done.

What We Were Burning

To be as realistic as possible, we could not acquire that many structures representative of construction found in the Metroplex. What we could do was acquire contemporary furnishings that are common to all jurisdictions. Mattresses, chairs, couches, and wood-component nightstands and dressers are very common products found in all bedrooms throughout the country. So, the experiment would need to be done on furnishings and contents rather than acquired structures.

Let's look at some accepted proven data regarding these furnishings. This will help us later when determining British thermal units (Btus), energy release, and so on.

Engineered wood-otherwise known as particleboard or oriented strand board (OSB)-is very common in lightweight bedroom furnishings. The use of these types of products has increased because of the inexpensive nature of the components-wood shavings, sawdust, and glues being the majority of the component structure. It is important to note that it is not wood! This is a manufactured product and is toxic as such. Although much progress has been made in recent years, these products will contain formaldehyde and off-gas this and CO as they burn. According to various sources, particleboard does have to meet new standards for formaldehyde concentration, but only as it pertains to building construction-not furniture or furnishings.

Figure 1: Live Burn Test Results

According to data, in 2004, 20.6 percent of all polyurethane foam produced was in furniture and bedding. This number has been increasing steadily over the past 10 years. It is important to note that in 2008, the U.S. Consumer Product Safety Commission requested a change in the standard for flame resistance in residential furniture. Since the majority of the standard is based on cigarettes being the primary ignition source, it is seeking to change the standard to something that will reflect other ignition sources.

There is also another change coming regarding foams and flame retardant. The Design for the Environment group, affiliated with the Environmental Protection Association (EPA), is proposing new standards for flammability in residential furniture. California has adopted a new standard, and all manufacturers were required to be compliant in that state as of January 2015. It remains to be seen whether or not the federal guidelines will mimic California's lead on this front.

Even with these changes, hydrocarbon products continue to have a major role in fire development and in furnishing construction in our dwellings. As a result, we also are seeing a higher energy release because of the manmade products. Important to remember is that one pound of wood will release approximately 8,000 Btus, while one pound of plastic will release approximately 19,900 Btus when ignited. Quick extinguishment will give victims a better chance of survival because of these toxic gases and higher temperatures.

The Prop

To more accurately represent what is happening in our residence fires, we settled on an average size room found in the southern United States. According to census data from 2009, 53 percent of the homes surveyed had three bedrooms. The average home size in the southern United States until the 2009 census had been growing. According to those figures, the home size actually had decreased to an average of 2,521 square feet-about a 100-square-foot decrease over previous data. Bedroom sizes continue to average between six feet by eight feet and 10 feet by six feet. Our prop used an average of 10 feet by 12 feet. This was also to accommodate room for suppression efforts and projected fire growth.

The Nozzles

This was an area in which we all have different opinions. Based on articles, phone calls, and our general usage, we decided to use both a smooth bore and a fog nozzle. These are the two most common and accepted nozzle types for our area.

As a side discussion, there are numerous types of fog nozzles today. What is becoming more commonplace in our area is the low-pressure fog nozzle. I have talked to some departments using these nozzles as an attempt to regulate nozzle reaction and increase maneuverability.

For our purposes, we used a Task Force Tips Flip Tip nozzle with a 11⁄8-inch smooth orifice. This allowed us to move rapidly between burns without having to switch nozzles. We did use a Vindicator nozzle for demonstration purposes for water only.

I realize this is a very narrow window of nozzle selection. Our original experiment was going to involve more variety in nozzle usage. But after consideration, we decided on our first attempt we needed to simplify things. We hope to follow this during 2015 with a study on nozzle selection. Results will vary depending on your local department's nozzle selection.

The Process

In any comparative process, there are fixed points of data. The fixed references we used were as follows:

In each burn, the material was ignited, and fire was allowed to grow to approximately 50 percent involvement. We were looking for initial ceiling temperatures to be between 800°F and 1,000°F and mid height temperature to be around 400°F to 500°F. It is also important to note that when referencing mid height, we are talking about the zone of three to four feet off the floor. This is where firefighter and victim survivability is most likely.

The Plano (TX) Fire Department advocates using a reinforced three-foot section of hose at the nozzle to keep any kinks from developing at the operator area.

Our Conclusions

From the data collected, some interesting patterns emerged. As you can see from Figure 1, CAFS allowed a 25 percent decrease in extinguishment time. Also note that the temperature differences between water and CAFS are comparatively close: only about a 10 percent difference at ceiling and two to three percent at the mid height level.

For data collection (and argument) purposes, there was a differential of plus or minus four seconds for variations in water burns and a differential of plus or minus 1.3 seconds for CAFS. CAFS extinguishment time averaged 8.1 seconds to 12.0 seconds for water extinguishment. As you can see, after 90 seconds, the temperatures basically are the same using either product.

This data would suggest no appreciable difference to victims or firefighters operating close to the floor. We have always assumed that water had a faster cooling effect-but this does show that with direct application it can be slower than using CAFS. And, ceiling temperatures look cooler with direct application onto the burning product. This can provide potential victims with a zone of survivability. Furthermore, this can also delay potential flashover effects, basically resetting or completely extinguishing the fire.

Again, to make sure we are all looking at the same thing, we are only talking about room-and-contents fires, not structure fires. The data suggests that CAFS is beneficial if you are looking for quick knockdown and little water damage to the structural components and surroundings.

The process we used was not to skew the data to an expected result. Our conclusions are based on direct observation, taking into account the variables mentioned above. Your results could vary depending on weather, crew makeup, and foam system or nozzle selection. We are not scientists, just a group of firefighters who pooled our resources together to try and get some useful information for our respective departments. There will be those who absolutely disagree with our results. I encourage you then to conduct your own experiments-that's the point of all this. You can do this in your own backyard!

Here are some points to remember:

Link del articulo original: http://www.fireapparatusmagazine.co...nt-of-contents-fires-using-water-vs-cafs.html

To CAFS or Not: A Comparative Study on Extinguishment of Contents Fires Using Water vs. CAFS

07/09/2015

BY STEVE GREEN

On December 12, 2014, the Southlake (TX) Fire Department, in cooperation with the Johnson County (TX) ESD1 Training Center, conducted a series of live fire experiments.

The following is a synopsis of what transpired during those live burns. This article is not meant to be a position paper on the use of compressed air foam systems (CAFS), nor does it prescribe one method of extinguishment over another. As always, follow your departmental guidelines regarding suppression techniques.

The What

CAFS is not a new piece of technology that just appeared on the fireground. In our area, we have had some departments actively deploying CAFS on the fireground for more than nine years. What is very much "up in the air" is its effective usage in urban environments here in the Metroplex area. The area known as the Metroplex encompasses Dallas/Fort Worth, Texas. Many departments have purchased these rigs and deployed them throughout their fleets. The manufacturers have been very good with initial training on operating the actual systems. There are also plenty of "experts" in the field of CAFS who are willing to come train your department. What is not standard nationwide is the acceptance of CAFS as an initial attack method. It is misunderstood and often not set up correctly-many apparatus operators are not familiar with the maintenance and upkeep of their systems. This altogether represents the higher costs often associated with the actual system. I have heard too many individuals comment that these systems are "a waste of money," that they are "glad it's out of service today," or comment that "we just need to stick with water." As with many "new" pieces of technology, training and experimentation are ways to overcome many of these misconceptions.

We could not acquire enough structures representative of construction found in the Metroplex. To be as realistic as possible, we acquired contemporary furnishings common to all jurisdictions. Mattresses, chairs, couches, and wood-component nightstands and dressers are very common products found in all bedrooms throughout the country. (Photos by author.)

The Idea

After the Southlake Fire Department acquired its newest engine, some members and I were flowing this apparatus in a parking lot during the spring of 2014. Not having used CAFS that much before, we found the results rather interesting. We had also borrowed a nozzle from another department to do some minimal testing. Afterward, we actually had more questions than answers. Basic operation of the system is easy, but the application results were different than when we used water. As a member of the Fire Instructors Association of North Texas (FIANT), I started contacting some of my other instructors about information, tactics, and so on as they related to CAFS. Now fast forward about three months to the summer of 2014. I put a study group together to evaluate the differences between CAFS and water. After about five to six months of planning, scheduling, and rescheduling, we managed, as a group, to get this done.

What We Were Burning

To be as realistic as possible, we could not acquire that many structures representative of construction found in the Metroplex. What we could do was acquire contemporary furnishings that are common to all jurisdictions. Mattresses, chairs, couches, and wood-component nightstands and dressers are very common products found in all bedrooms throughout the country. So, the experiment would need to be done on furnishings and contents rather than acquired structures.

Let's look at some accepted proven data regarding these furnishings. This will help us later when determining British thermal units (Btus), energy release, and so on.

Engineered wood-otherwise known as particleboard or oriented strand board (OSB)-is very common in lightweight bedroom furnishings. The use of these types of products has increased because of the inexpensive nature of the components-wood shavings, sawdust, and glues being the majority of the component structure. It is important to note that it is not wood! This is a manufactured product and is toxic as such. Although much progress has been made in recent years, these products will contain formaldehyde and off-gas this and CO as they burn. According to various sources, particleboard does have to meet new standards for formaldehyde concentration, but only as it pertains to building construction-not furniture or furnishings.

Figure 1: Live Burn Test Results

According to data, in 2004, 20.6 percent of all polyurethane foam produced was in furniture and bedding. This number has been increasing steadily over the past 10 years. It is important to note that in 2008, the U.S. Consumer Product Safety Commission requested a change in the standard for flame resistance in residential furniture. Since the majority of the standard is based on cigarettes being the primary ignition source, it is seeking to change the standard to something that will reflect other ignition sources.

There is also another change coming regarding foams and flame retardant. The Design for the Environment group, affiliated with the Environmental Protection Association (EPA), is proposing new standards for flammability in residential furniture. California has adopted a new standard, and all manufacturers were required to be compliant in that state as of January 2015. It remains to be seen whether or not the federal guidelines will mimic California's lead on this front.

Even with these changes, hydrocarbon products continue to have a major role in fire development and in furnishing construction in our dwellings. As a result, we also are seeing a higher energy release because of the manmade products. Important to remember is that one pound of wood will release approximately 8,000 Btus, while one pound of plastic will release approximately 19,900 Btus when ignited. Quick extinguishment will give victims a better chance of survival because of these toxic gases and higher temperatures.

The Prop

To more accurately represent what is happening in our residence fires, we settled on an average size room found in the southern United States. According to census data from 2009, 53 percent of the homes surveyed had three bedrooms. The average home size in the southern United States until the 2009 census had been growing. According to those figures, the home size actually had decreased to an average of 2,521 square feet-about a 100-square-foot decrease over previous data. Bedroom sizes continue to average between six feet by eight feet and 10 feet by six feet. Our prop used an average of 10 feet by 12 feet. This was also to accommodate room for suppression efforts and projected fire growth.

The Nozzles

This was an area in which we all have different opinions. Based on articles, phone calls, and our general usage, we decided to use both a smooth bore and a fog nozzle. These are the two most common and accepted nozzle types for our area.

As a side discussion, there are numerous types of fog nozzles today. What is becoming more commonplace in our area is the low-pressure fog nozzle. I have talked to some departments using these nozzles as an attempt to regulate nozzle reaction and increase maneuverability.

For our purposes, we used a Task Force Tips Flip Tip nozzle with a 11⁄8-inch smooth orifice. This allowed us to move rapidly between burns without having to switch nozzles. We did use a Vindicator nozzle for demonstration purposes for water only.

I realize this is a very narrow window of nozzle selection. Our original experiment was going to involve more variety in nozzle usage. But after consideration, we decided on our first attempt we needed to simplify things. We hope to follow this during 2015 with a study on nozzle selection. Results will vary depending on your local department's nozzle selection.

The Process

In any comparative process, there are fixed points of data. The fixed references we used were as follows:

- 200 feet of 1¾-inch attack line.

- Three-person crew.

- Application of product directly to the fire.

In each burn, the material was ignited, and fire was allowed to grow to approximately 50 percent involvement. We were looking for initial ceiling temperatures to be between 800°F and 1,000°F and mid height temperature to be around 400°F to 500°F. It is also important to note that when referencing mid height, we are talking about the zone of three to four feet off the floor. This is where firefighter and victim survivability is most likely.

The Plano (TX) Fire Department advocates using a reinforced three-foot section of hose at the nozzle to keep any kinks from developing at the operator area.

Our Conclusions

From the data collected, some interesting patterns emerged. As you can see from Figure 1, CAFS allowed a 25 percent decrease in extinguishment time. Also note that the temperature differences between water and CAFS are comparatively close: only about a 10 percent difference at ceiling and two to three percent at the mid height level.

For data collection (and argument) purposes, there was a differential of plus or minus four seconds for variations in water burns and a differential of plus or minus 1.3 seconds for CAFS. CAFS extinguishment time averaged 8.1 seconds to 12.0 seconds for water extinguishment. As you can see, after 90 seconds, the temperatures basically are the same using either product.

This data would suggest no appreciable difference to victims or firefighters operating close to the floor. We have always assumed that water had a faster cooling effect-but this does show that with direct application it can be slower than using CAFS. And, ceiling temperatures look cooler with direct application onto the burning product. This can provide potential victims with a zone of survivability. Furthermore, this can also delay potential flashover effects, basically resetting or completely extinguishing the fire.

Again, to make sure we are all looking at the same thing, we are only talking about room-and-contents fires, not structure fires. The data suggests that CAFS is beneficial if you are looking for quick knockdown and little water damage to the structural components and surroundings.

The process we used was not to skew the data to an expected result. Our conclusions are based on direct observation, taking into account the variables mentioned above. Your results could vary depending on weather, crew makeup, and foam system or nozzle selection. We are not scientists, just a group of firefighters who pooled our resources together to try and get some useful information for our respective departments. There will be those who absolutely disagree with our results. I encourage you then to conduct your own experiments-that's the point of all this. You can do this in your own backyard!

Here are some points to remember:

- A 200-foot section of 1¾-inch line charged with water contains approximately 24.98 gallons of water. So when the initial charged line is in place, unless you have bled that water off, the first approximately 30 seconds are really just Class A foam (or wet foam), not CAFS.

- To maintain the proper foam/water/air ratio, Alvarado (TX) Fire Department personnel have advocated leaving the bail cracked slightly to allow the system to bleed out. When the knob is fully opened, the mixture is constant because air has been circulating through the system. A more dry foam product is readily seen. It is a very effective technique.

- The Plano (TX) Fire Department advocates using a reinforced three-foot section of hose at the nozzle to keep any kinks from developing at the operator area.

- The water meter for the day indicated this total experiment used 2,894 gallons of water. That is nine total burns plus flushing lines and some actual practice post testing. CAFS does not use up your second most precious asset on the fireground: water.